In technical ceramics, hydraulic presses are used to produce ceramic components – with uniform density and great lengths, as well as small, complex component geometries. Depending on physical properties or optical characteristics the pressed part should have, a difference is made between two pressing processes, the

![]()

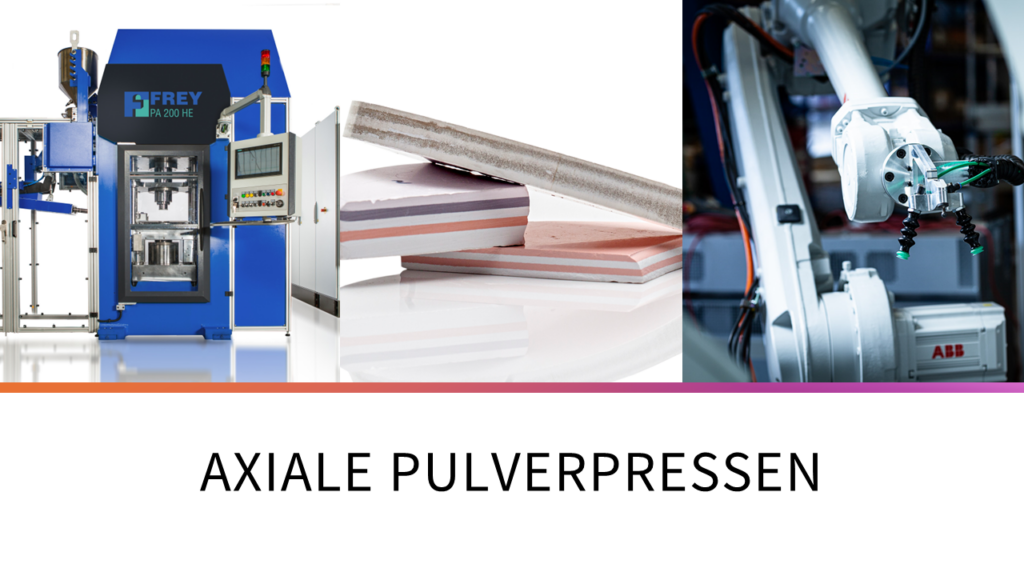

axial pressing

![]()

and the isostatic pressing.

Both isostatic and axial ceramic pressing are technologies that uses high pressure to compact ceramic powder, it transforms the material from a loose powder into a green part.

After the creation of the green part, the pressed part has to go through a few more steps until the end product is created – these can be sintering processes, turning and milling operations or sizing presses.

In the video you can see some of those green parts.