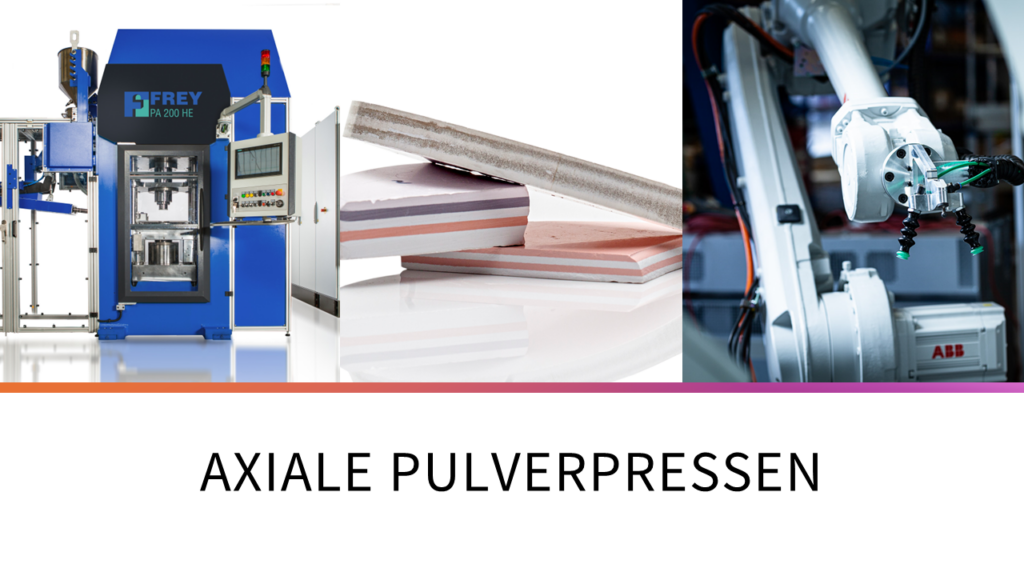

Versatility and Precision in Axial Powder Presses:

Our axial powder presses stand out due to their modular design and the ability to customize them individually. Whether you are using plastic powder, metal powder, heavy metal powder, or ceramic powder, our presses are equipped to handle every challenge. Thanks to high-precision control systems, we guarantee repeatability accuracy of ±0.01 mm, enabling exact pressing with consistent force and position.

Specific customizations for Axial Powder Presses:

The PA series of our powder presses offers tailored solutions for various applications:

- Multilayer filling

- Different part handling options

- Quick adapter change variants

- Comprehensive process control

Maximal efficiency with Axial Powder Presses:

Our specially developed hydraulic and electronic systems ensure that our powder presses achieve the highest precision and efficiency in both withdrawal and counter-pressing operations.

Fully Automated Operation with Axial Powder Presses:

Our systems enable full automation of the pressing process. From autonomous filling systems to part removal, the entire process can be automated to ensure maximum efficiency and production speed. This allows seamless integration into existing production lines and significantly reduces manual effort.

Energy Efficiency in Axial Powder Presses:

With our unique servo-hydraulic system, you can save up to 70% energy. This globally unique technology enables significant reductions in operating costs and supports more sustainable production