Automation has emerged as one of the most groundbreaking developments in the manufacturing industry over the past few years. Particularly in powder metallurgy, automation and robotic solutions offer significant advantages, ranging from increased efficiency to optimized production processes. Frey Systeme offers innovative automation solutions specifically designed to meet the demands of modern Industry 4.0.

Why Automation in Powder Metallurgy?

Powder metallurgy is a highly specialized field of material processing that demands precision and efficiency. In such a complex environment, errors or inefficient processes can have significant impacts on product quality and operational costs. Automation technologies help to overcome these challenges by enabling standardized operations, ensuring consistency, and increasing production speed

Benefits of Automation:

- Increased Efficiency: Automated systems can operate around the clock without fatigue or performance fluctuations, leading to a significant increase in production capacity.

- Reduction of Errors: By utilizing robotics, a consistently high quality of end products can be ensured, minimizing human error.

- Cost Savings: In the long term, automation solutions can substantially reduce operational costs and optimize material usage.

- Addressing Skills Shortage: Automation helps bridge the gap caused by a lack of skilled labor.

Custom specific automation Solutions

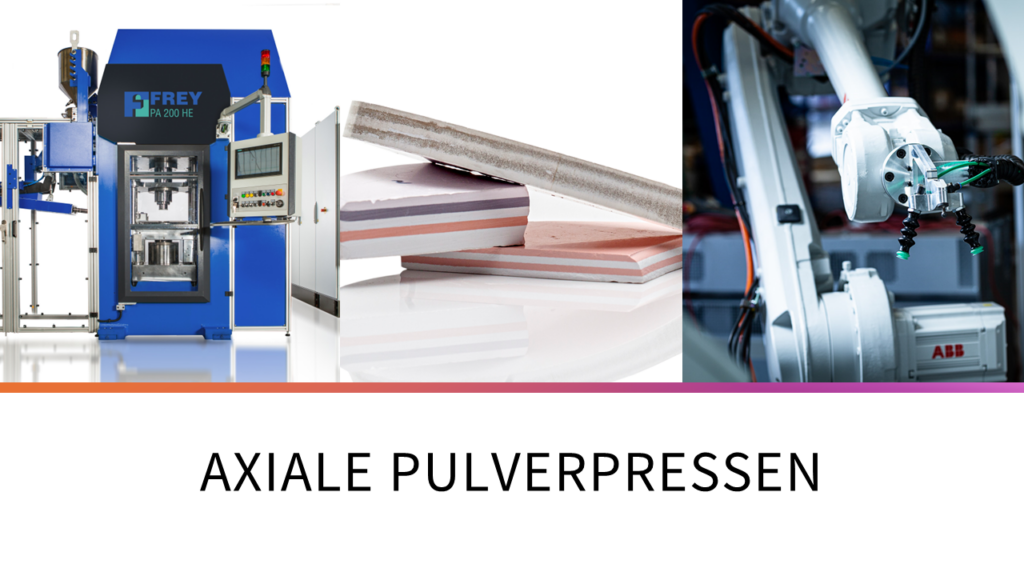

Frey Systeme offers custom automation solutions tailored to the specific needs and requirements of our clients. This flexibility ensures that companies benefit not only from increased productivity but also from a solution that perfectly fits their existing structures.

The Services of Frey Systeme:

- Individual Customization: Each solution is carefully crafted to meet the unique requirements of the respective company, whether in process optimization, material handling, or final processing.

- Modern Robotics: Our robotic systems are designed to handle complex tasks with the utmost precision and speed. They can be seamlessly integrated into existing production facilities, offering unparalleled efficiency.

- Seamless Integration: Frey Systeme’s solutions perfectly integrate into existing production environments, ensuring a smooth transition to an automated production line.

The Role of Automation in Industry 4.0

Industry 4.0 marks the transition to smart factories, where cyber-physical systems connect the physical world with the virtual world. By utilizing automation technologies, companies can conduct real-time data analysis, promote process optimization, and enhance manufacturing flexibility. Frey Systeme provides solutions that support this transformation, enabling companies to remain competitive.

Benefits of Industry 4.0:

- Connected Production: Our automation solutions enable the complete networking of your production facilities, simplifying real-time monitoring and control.

- Real-Time Data Analysis: With our systems, you can gather insightful data that helps you make informed decisions and continuously improve your processes.

- Continuous Process Improvement: The integration of automation into your production processes allows you to constantly unlock new efficiency potentials and quickly adapt to changing market demands.

Challenges and Opportunities of Automation

While automation offers numerous benefits, there are also challenges to be addressed. These includes the need for careful planning and implementation and ensuring that staff is adequately trained to handle new technologies. However, the opportunities arising from automation are immense, including the potential to enter new markets and enhance competitiveness.

If you would like to learn more about the possibilities of automation or are interested in a custom-made solutions for your company, do not hesitate to contact us. Our experts are ready to assist you